Our Services

- Home

- Our Services

- OUR SERVICES

What We Do Beyond Products

From installation and validation to chemical testing and cleanroom support — we ensure your systems run compliant, efficient, and audit-ready.

At Fayme Engineering, we don’t just manufacture water systems — we deliver end-to-end service solutions tailored for industries where precision and compliance are non-negotiable. Our on-site offerings include expert piping work, validation testing, QA support, and more. Each service is executed by industry-trained technicians, fully aligned with WHO, GMP, and FDA standards.

- OUR CORE SERVICES

Expert Services That Power Compliance

API Plant Piping Work

Custom stainless steel piping systems for purified water, steam, and

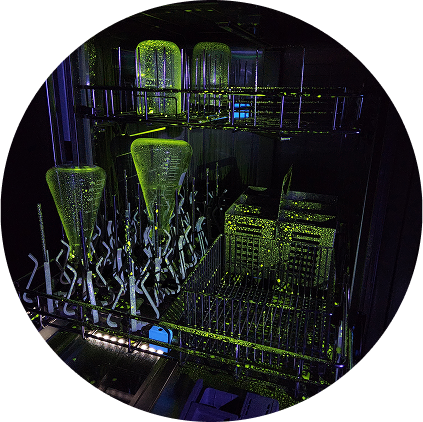

Riboflavin Testing

Fluorescent dye testing for validating CIP (Clean-in-Place) systems. Ensures 100%

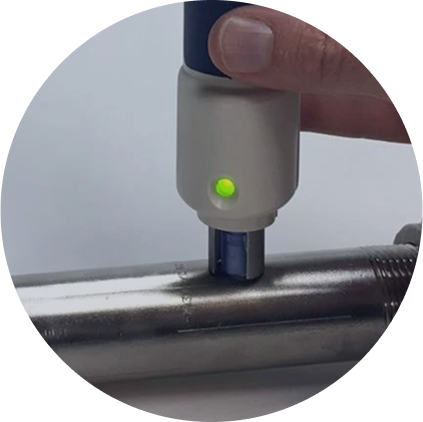

Hydro Test

High-pressure water testing to verify the mechanical strength and leak-proof

Passivation

Chemical passivation of stainless steel to remove iron contamination and

Pneumatic Test

Compressed air-based testing for detecting leaks in systems that can’t

- WHY FAYME?

Precision. Compliance. Reliability.

Delivered by in-house engineers and certified technicians

Fast execution with minimal downtime

Built to GMP, ISPE, and global cleanroom standards

Fully customized based on your process and plant layout

End-to-end reports, test logs, and documentation

Compliant with FDA, WHO, and pharmaceutical validation protocols

- TALK TO AN EXPERT

Need Expert Support for Installation or Validation?

Our service team is ready to assist you — from initial setup to full audit documentation.