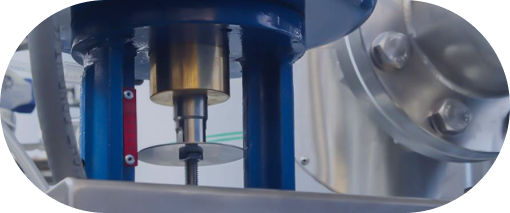

Orbital welding is an automated TIG (GTAW) welding process used for joining stainless steel pipes in high-purity environments. It delivers consistent, high-quality welds with no human error — making it ideal for pharmaceutical, biotech, and cleanroom-grade piping systems that require contamination-free, traceable joints.