Proposals are Welcome

Find out more about available solutions by contacting Fayme Engineering

Home / Water Treatment Solutions for Pharmaceutical Industry

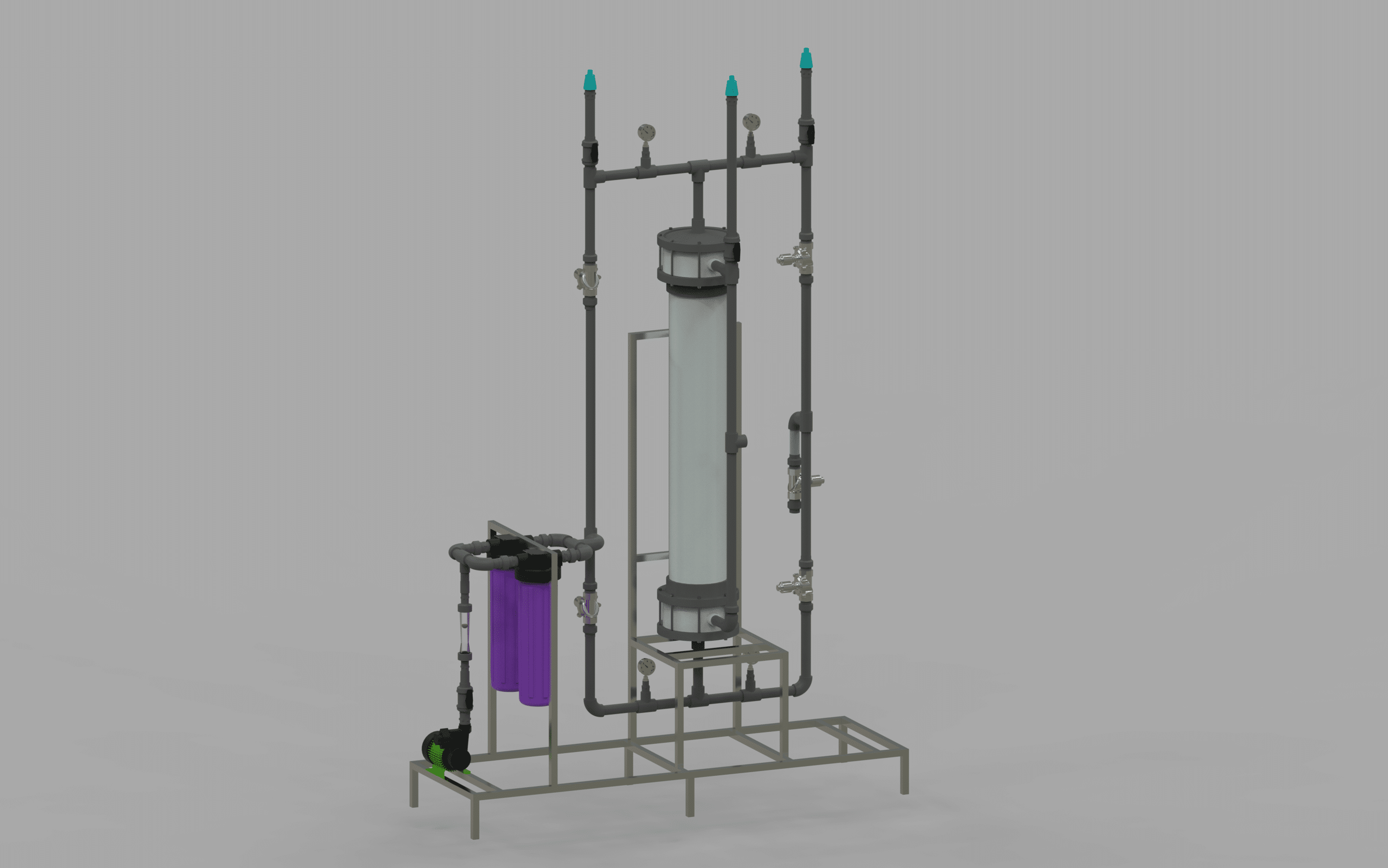

With cutting-edge knowledge and technology, Fayme Engineering is leading the way in reinventing water treatment solutions for the pharmaceutical Industry. Designing and implementing complete water treatment solutions that are tailored to the particular requirements of the pharmaceutical industry demonstrates our dedication to excellence. For the pharmaceutical business, we at Fayme Engineering specialise in offering water purification solutions that surpass traditional norms. Our dedication to precise engineering and innovation guarantees the delivery of dependable, high-performing systems that are specifically designed to satisfy the demanding needs of the pharmaceutical production industry. Our pharmaceutical purified water treatment machine stands as a testomony to our determination to first-rate purity. Meticulously designed, these structures are a necessary part of pharmaceutical tactics where water purity is of utmost importance. Fayme Engineering’s purified water remedy machine ensures a regular and first-rate supply of water, aligning seamlessly with the stringent standards of the pharmaceutical enterprise.

As a trusted companion in the pharmaceutical area, Fayme Engineering’s water treatment solutions aren’t only compliant with enterprise requirements however are also designed for top-quality efficiency and reliability. We understand the essential role that water purity performs in pharmaceutical operations, and our systems are engineered to make a contribution to the overall fulfilment and compliance of those techniques. Fayme Engineering’s dedication to precision engineering, innovation, and exceeding industry expectations positions us as a frontrunner in turning in water remedy answers for the pharmaceutical enterprise. Our structures are a reliable preference for pharmaceutical institutions searching for top-tier answers that prioritize excellent, purity, and compliance.

FAQ of Water Treatment Solutions for Pharmaceutical Industry

The pharmaceutical business uses a variety of water types, including ultrapure water, water for injection (WFI), and purified water (PW). To satisfy strict quality requirements for formulation, cleaning, and manufacturing procedures, these kinds must be treated to get rid of pollutants, microbes, and impurities. Appropriate water treatment eliminates the possibility of contamination in pharmaceutical products and guarantees adherence to legal standards.

Water plays a significant role in the manufacturing of pharmaceuticals, being utilised for everything from equipment cleaning to drug development. To guarantee that products are safe, efficient, and free of impurities, high-quality water is necessary. Inadequate water quality can jeopardise the drug’s stability, impact its therapeutic effectiveness, and endanger patients’ health. Therefore, to maintain the requisite quality standards, strict water treatment and monitoring are required.

Reverse osmosis (RO), deionisation, ultrafiltration, distillation, and ultraviolet (UV) disinfection are some of the water treatment technologies used in the pharmaceutical business. By removing dissolved solids, organic contaminants, microbes, and endotoxins, these techniques assist guarantee that the water satisfies requirements for use in pharmaceuticals. To get the appropriate water quality, these technologies are frequently combined.

Since reverse osmosis (RO) can eliminate up to 99% of dissolved salts, organic materials, and bacteria from water, it is a popular water purification technique in the pharmaceutical sector. It works by pushing water through a semi-permeable membrane that lets clean water flow through while filtering out impurities. RO aids in achieving the water quality required for a range of pharmaceutical uses, such as manufacturing, cleaning, and lab work.

Organisations like the European Pharmacopoeia (EP), the U.S. Pharmacopoeia (USP), and other national regulatory agencies establish the criteria for water treatment in the pharmaceutical sector. These guidelines specify the permissible contamination levels for several water grades, including Purified Water (PW) and Water for Injection (WFI). In order to guarantee continuous compliance, the laws explicitly outline validation and monitoring procedures.

By taking into account variables like the water supply, production volume, and the quality standards required for different applications, water treatment systems can be customised to match the particular needs of a pharmaceutical plant. Combining various treatment technologies, modifying system capacity, and putting in place automated monitoring and control systems are a few examples of customisation. This method guarantees that the treated water continuously satisfies legal requirements and efficiently supports the facility’s operational requirements.

Our Assembly Unit for pharmaceutical Water Treatment Plant offers the latest and most advanced technology for treating water. We understand the importance of water purity and safety, and that’s why we ensure that our assembly units are of the highest quality. Our skilled technicians and engineers use the latest tools and techniques to manufacture these units, ensuring maximum efficiency and durability. Our assembly units are suitable for both industrial and domestic use, and we customize them to meet your specific needs. We take pride in being a trusted name in the water treatment industry and strive to provide you with the best possible service.

Fayme Engineering Pvt Ltd’s water treatment facilities are renowned for their high quality, and after passing even more rigorous quality checks, they are supplied and exported to the clients. We furthermore offer a full range of accessories needed for water treatment plant requirements. Although the quality of the freshwater provided by municipal authorities or bore well water may be up to par with local requirements, it may not be sufficient for institutions of higher learning and commercial industries. Ordinary tap water and bore well water may include lead and iron as well as overall hardness and dissolved metals. It could contain nitrates, chlorine, and mineral salts, which could have an immediate impact on the functionality of any commercial building’s utility equipment, including those in hotels, hospitals, theaters, shopping malls, retail stores, restaurants, schools, and colleges, as well as their boarding facilities. We provide the highest caliber Assembly Unit for Water Treatment Plant in Gujarat. Our business is highly specialized in this area and have provided services to thousands of customers around the nation. We employ the highest quality raw materials to develop our whole line, and they are all up to the needed level, promoting their use across the world.

Are you looking for Customized Pure Water Treatment Solutions for pharmaceutical industry ? Look no further! We offer a wide range of pure water treatment solutions that are tailored to meet your specific needs. Our team of experts will work with you to understand your requirements and provide you with a solution that is both efficient and cost-effective. Whether you need a solution for industrial or domestic use, we have you covered. We use only the latest technology and equipment to ensure that your water is treated to the highest standards of purity and safety. With our customized solutions, you can be sure that your water is safe to use and free from contaminants.

Customized water filtration systems are offered by Fayme Engineering Pvt. Ltd. for usage in highly polluted water sources found all over the world. These systems are specifically created to address a range of water quality challenges and deliver pure, secure water with simple, efficient fixes. With the help of our specialised systems, we can eliminate unpleasant flavours, colours, and odours as well as undesired pollutants like chlorine, iron, heavy metals, organic waste, viruses, and microbiological organisms. There are several of pre-built water filtering systems available. It might be difficult, tedious, and fruitless to find the ideal system to meet your precise demands. Custom water filtration systems designed to your specifications are the obvious answer. Customized Pure Water Treatment Solution are created, developed, and manufactured by Fayme Engineering Pvt. Ltd.

Our EDI system in water treatment plants is the most advanced technology available for purifying water. EDI (Electrodeionization) is a process that uses electricity to remove impurities from water, resulting in ultra-pure water that is safe for use in a variety of industries. Our team of experts will install and maintain the EDI system in your water treatment plant, ensuring maximum efficiency and durability. The EDI system is an environmentally friendly solution that uses no chemicals, and requires very little maintenance. With our EDI system, you can be sure that your water is purified to the highest standards of purity and safety. Trust us to provide you with the best possible service and solutions for your water treatment needs.

Ion exchange membranes, electricity, and resin are all used in the electrically powered water treatment process known as Electrodeionization (EDI) to remove ionised species from water. Typically used in combination with reverse osmosis (RO) and other purification technologies, Electrodeionization (EDI) systems remove ions from aqueous streams. Our premium modules consistently generate ultra-pure water up to 18.2M/cm. Either continuous or sporadic EDI operation is possible. Deionizing water with Electrodeionization is environmentally friendly. Electrodeionization units are the deionization of the future since they don’t require expensive chemical maintenance and have almost no downtime.

The capacity of water to carry current is referred to as conductivity. It is a significant factor in determining the quality of the water. Low conductivity refers to a decrease in the water’s capacity to conduct electricity, and such water is of the highest calibre. This is owing to the fact that, in contrast, if water contains ions from dissolved impurities such as dissolved salts and other inorganic components like chlorides, sulphides, carbon compounds, etc., it will conduct current because of the high ion concentration. Therefore, water with a higher conductivity is of worse quality since it has a greater capacity to transmit electricity.

Electro-Deionization (EDI) machinery may be used to provide the high purity water needed to meet the growing demand. To create deionized water, the EDI method substitutes traditional DI mixed resin beds. Contact us now for more information about the EDI system in water treatment plants.

Proposals are Welcome

Find out more about available solutions by contacting Fayme Engineering

Contact Us

Our Products

Contact Us

Our Products

Copyright © 2025 FAYME ENGINEERING PVT LTD | Powered by: #1 Vinayak InfoSoft- SEO company Ahmedabad